AUSE-V1 Search and Rescue Flight Simulator

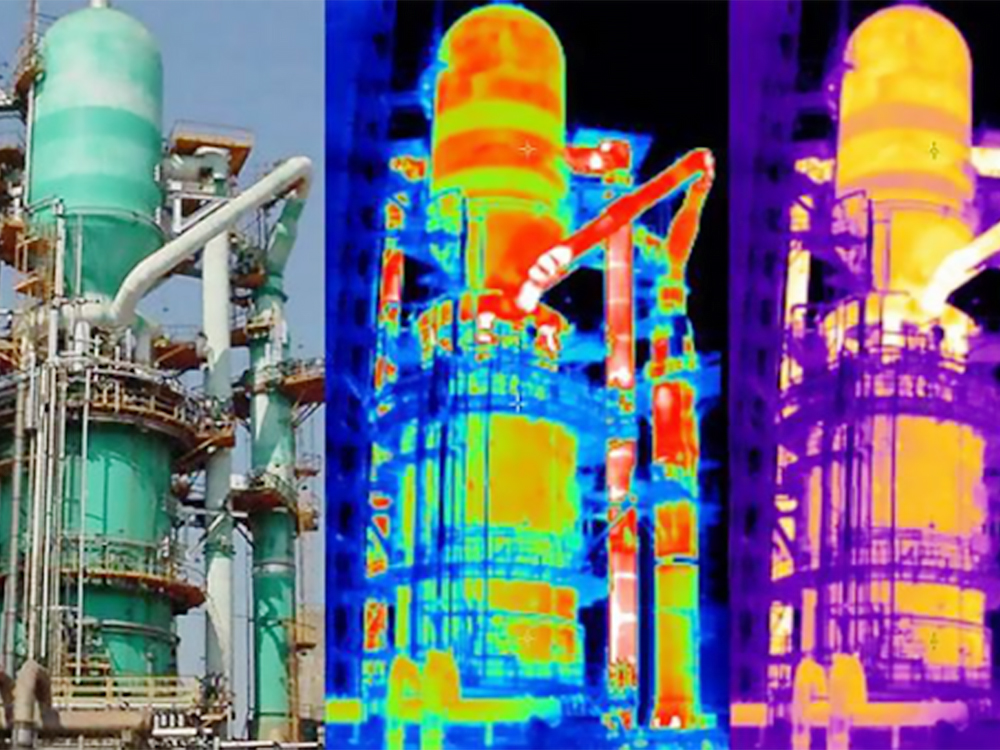

Petroleum is a very important resource in nowadays society, and the stability of large equipment in petrochemical plants and oil and gas pipelines is very important. The equipment and facilities in chemical plant are huge and complex, working under high temperature and high pressure conditions. They are exposed to the air for a long time and suffer the rain and wind, which is easy to have serious leakage accidents due to aging, corrosion and other problems. In order to ensure the normal operation of the chemical plant, it is necessary to conduct the routine inspections of the chemical plant and pipeline facilities to eliminate the hidden dangers of the equipment and pipelines in time. UAV patrol inspection is the new inspection technology that uses drones to carry other auxiliary equipment to inspect chemical plants. It can effectively supplement the patrol inspection areas that manual patrol inspection is difficult or difficult to reach by manual inspection. It greatly improves the inspection efficiency and ensure the normal operation of the installation equipment.

Purpose and Significance

UAV operators need to undergo a lot of flight skills training before they start to work, and only after passing the certification exam can they be employed with certificates. However, it will take some time for the members with certificates to master the patrol inspection flight requirements and the response skills in emergency. The chemical plant is an important area, and the UAV crashes during the flight may cause damage to personnel and equipment in the plant. Therefore, the requirements for the flight skills of the operators are extremely high. In order to strengthen the operational skills of operators to prevent flight accidents, it is necessary to develop a high-tech multi-rotor UAV simulating training system, which can further reproduce the process of multi-rotor UAV patrol inspection and control, so that the staff can be familiar with multi-rotor UAV operation and chemical plant patrol inspection skills. At the same time, the staff can have the opportunity to carry out targeted repeated skill exercises to improve the business skills of themselves.

Research Case

We have conducted an in-depth investigation on the “300,000 tons/year coal to ethylene glycol project” of Guiyang Qianxi Coal Chemical Investment Co., Ltd., which has already invested in UAV patrol inspection. which has already invested in UAV patrol inspection. Qianxi Coal Chemical Plant covers an area of 66.7 hectares (666667 m2). The main reaction devices are divided into: coal storage and transportation device, coal gasification device, air separation device, conversion device, low temperature methanol washing device, sulfur recovery, ethylene glycol device, etc.

Patrol Inspection Equipment: explosion-proof UAV, visible light and infrared PTZ, explosion detection instrument (gas detection instrument), megaphone.

Patrol Inspection Focus: safety inspection of plant , high-rise reaction equipment, power inspection of plant, patrol inspection of high temperature reaction equipment such as torches, etc.

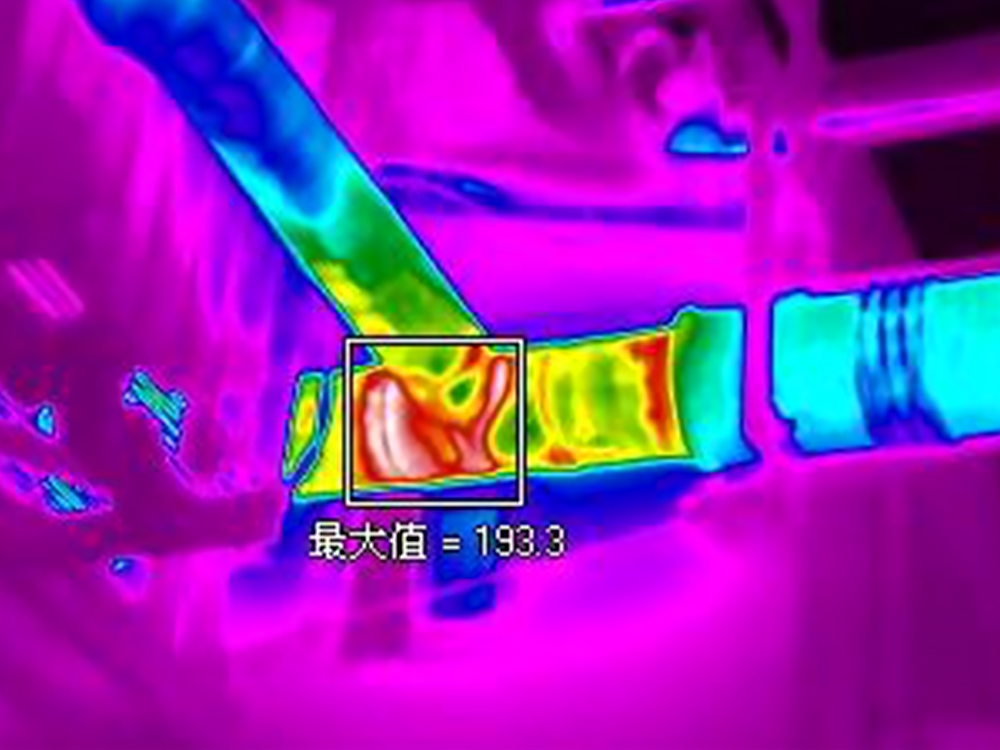

Inspection Function: UAV equipped with explosion detection equipment to conduct gas leak patrol inspection in the plant, plant safety patrol inspection, UAV equipped with infrared equipment patrol inspection and the location of leakage source, the peeling off of surface coating for high-rise reaction device, the patrol inspection of overhead power lines for plant use, etc.

Project Development Content & Implementation Plan

3D Scene Modeling of Petrochemical Plant

Scene Oblique Photography Modeling of Chemical Plant

Analyze and use the data of UAV application scene in the real chemical plant, and use the oblique photography technology to perform 3D modeling of the whole plant area to truly restore the full picture of the chemical equipment and layout of the large petrochemical plant. Import the constructed 3D modeling into the 3D engine UE.

Refined Modeling of Key Equipment

Patrol inspection UAV and mission equipment will perform refined modeling of reaction devices and key inspection devices and parts of chemical plants based on drawings, and adopt 3dsMax tools according to design drawings of devices to complete the detailed modeling of conventional typcial oil refining equipment patrol inspection: torch, storage tank field, atmospheric and vacuum distillation unit, catalytic cracking unit, catalytic reforming unit, hydrogenation unit, delayed cooking unit, sulfur recovery unit, etc. Complete the detailed modeling of conventional typical chemical, equipment patrol inspection: ethylene unit, propylene unit, separation unit, conversion unit, etc.

UAV and Modeling of Patrol Inspection Equipment

Really restore the UAV equipped with mission equipment: infrared thermal imaging camera, telephoto zoom camera, megaphone, explosion test instrument (gas leak test), equipped with mold (mission equipment expansion module). Realize the real restoration of mission equipment details and application methods.

Petrochemical UAV Patrol Inspection Process & Subject Development

Patrol Inspection of High-rise Reaction Device

The system conducts refined modeling of important high-rise reaction devices, such as simulating faults and defects of high-rise equipment and the corrosion and shedding of building exterior coatings; simulating UAV to patrol key equipment of torch facilities above 80 meters, such as torch high-altitude igniters and permanent light thermocouples. And the system correspondingly sets the faults and defects of related equipment.

Oil & Gas Leak Detection & Leak Location

Conduct leak detection of important equipment and facilities in the plant area by simulating visible light day and night and infrared scenes. Restore the leak patrol inspection of UAV daily inspection equipped with a gas detector in the plant area. Under emergency conditions, it is equipped with visible light and infrared equipment to quickly confirm and locate the leak source of devices.

Plant Power Patrol Inspection

Conduct refined modeling of power supply line facilities and parts in the plant area, and develop power supply inspection module in the UAV plant area. The UAV conducts simulated patrol inspections on the overhead power supply lines and equipment in the plant area, and develops corresponding defect modules. Train the ability of fast recognition and handling of operators to ensure the safety of power usage in the plant area.

Basic Flight Skills Training

Design basic flight skills training for UAV such as take off, landing, hovering, figure eight flight and four-sided flight route according to relevant forensics and flight operation requirements of key skill points for flight operations to exercise basic flight skills of operators.

Environmental Impact Factors Research and Unexpected Situation Response Development

Research and develop the impact of unexpected accidents such as electromagnetic interference, meteorological change, and sudden change in wind direction between high-rise buildings in the chemical plant area on UAV and the response strategies and skills of operators. Add the influencing factors (icing, cloudy, sunny, temperature, wind, cloud, rain, snow, fog, GPS failure, collision, etc.) to the patrol inspection scene. Train the response ability in emergency. Study the procedures and elements of chemical plant patrol inspection. Formulate a quality evaluation plan of simulating operating operation shooting data. So that the staff can master the UAV patrol inspection skills in the training, and comprehensively train the operators from the three aspects of patrol inspection business logic, safety awareness and operation skills to allow them to improve the accident handling ability and business level through practice and ensure the stable and safe operation of chemical plants.

Key Technology

Real-time Simulation of UAV Flight Characteristics Based on Airsim+pixhawk

In view of the complex environment characteristics during the flight of real UAV patrol inspection, study the flight characteristics of different types of common UAV under different environmental conditions and the effects of these factors on the flight characteristics and handling of the UAV. Use Pixhawk+Airsim to realize the simulation of aircraft characteristics. Build an aircraft driving environment in a real scene based on Microsoft AirSim to provide a realistic environment and simulate the power and sensing of the UAV and give users the most realistic operating experience.

High-precision 3D Scene Modeling

Use data from chemical plant patrol inspection scenes to construct 3D models of UAV, equipment modules, scenes, chemical equipment and pipelines in the simulation system, and perform refined modeling based on the drawing data, and import the constructed 3D modules into the 3D engine UE. The three-dimensional scene has the friendly visual interface, complete model base effects, clear model details, high-quality particles and realistic effects,

Interactive Integration of VR and Simulation

Develop head-mounted devices as the main input tool to enable learners to be completely surrounded by virtual scenes and synchronize real-time spatial positioning. It no longer uses traditional input methods such as button handles and consoles, and integrates real UAV handles and flight control to achieve the same operation mode as the actual UAV operation.

Simulation of Natural Influence Factors

Study the impact of complex factors (icing, cloudy, sunny, temperature, wind, cloud, rain, snow, fog, GPS failure, collision, etc.) on the performance and handling of UAV. In view of the complex terrain and environment characteristics of chemical plants, study the flight characteristics of different types of common UAV in chemical plant reaction devices and complex terrain environment conditions between high-rise buildings and the effects of these unfavorable factors on the flight characteristics and handling of the UAV. Integrate these factors into the simulation system to restore the UAV line patrol operation in the real and complex environment, and train the response ability of operators in emergency.

联系我们

如有任何问题,我们的无人机专家随时为您提供帮助